Price volatility, changing market dynamics and regulatory and societal pressure to decarbonise are all reasons why energy operators are keen to get better oversight across their supply chain and understand exactly what is happening across vast, remote, often hard-to-reach, infrastructure. In fact, as many as one-third of senior energy leaders say their company is already dealing with the fallout of a lack of supply chain resilience.

As operators look for ways to solve these competing challenges, satellite-enabled industrial monitoring – pushing data towards advanced operational AI platforms – can make the difference. You can’t manage what you can’t measure, and connected IoT and AI can be a great facilitator in solving this challenge. Implementing these solutions can create a more efficient network that can yield greater return on investment, and it is often more sustainable and safer for employees.

Before we dive into the various applications, let’s explain exactly what we mean by terms like ‘satellite-enabled IoT’ and ‘operational AI’. In some ways, these have become go-to buzzwords in recent years – particularly after AI hit the mainstream with ChatGPT and with similar applications gaining popularity with everyday users.

Put simply, IoT refers to the huge range of sensors, devices and connected machinery that are the enablers of “smart” in today’s world. This has been around for some years now, and businesses across most industries have either embraced or are embracing Industrial IoT (IIoT) applications in various forms.

Of course, for connected IoT to work, you need connectivity. For oil and gas operators and utilities operating vast networks in remote regions, globally available satellite connectivity is the most reliable, resilient and secure choice – or is often used to augment or back up existing terrestrial coverage.

See Also:

However, with all this satellite-enabled IoT providing huge volumes of data across not just supply chains but also assets, infrastructure, fleet and even employees, the results can be overwhelming. That is where operational AI comes in. AI platforms consolidate these huge data sets into accessible information and actionable insights, helping an organisation make better decisions, more quickly.

Satellite-enabled IoT applications in the field

So, how do these platforms work with supply chains in practice? Connected assets can offer visibility across the entire system, allowing operators to easily track the movement of goods, equipment and personnel across the globe.

According to KPMG, supply chain operators and organisers should aim for “’control tower’ visibility on key real-time indicators; being able to maneuver your supply chain beyond your own business borders; and building real-time collaboration with your ecosystem of supply chain partners will likely be critical – all done using digital capabilities”. Reliable, resilient satellite coverage providing real-time data can enable exactly that.

Telemetry data such as location, speed and engine diagnostics can become available to control centre operators, no matter where these networks extend. This gives operators the tools to effectively manage diverse fleets of vehicles and complex links in the supply wherever they are in the world, because they can rely on one global satellite network to ensure equipment and cargo is delivered on time. The more complex the operation, the greater potential benefits there are from enabling AI to support engineers with operational decision-making.

On this topic, we are also finding operators of critical industries like oil and gas and utilities increasingly want to prioritise not just visibility of their supply chain, but security too. Across the board, organisations are adapting to the increasing complexity of cyberattacks and escalating risk presented by additional connected technology. Almost half of global organisations consider cybersecurity an important operational challenge for their supply chains by 2026.

In Viasat’s case, we provide a team of highly experienced cybersecurity analysts dedicated to preventing cybersecurity threats. This provides a force multiplier, while avoiding costly training and employing staff who will need to keep up with the latest vulnerabilities. We employ technologies including an arsenal of firewalls, probes and event management systems that collect and monitor data as it moves across platforms.

Enabling remote maintenance and operations

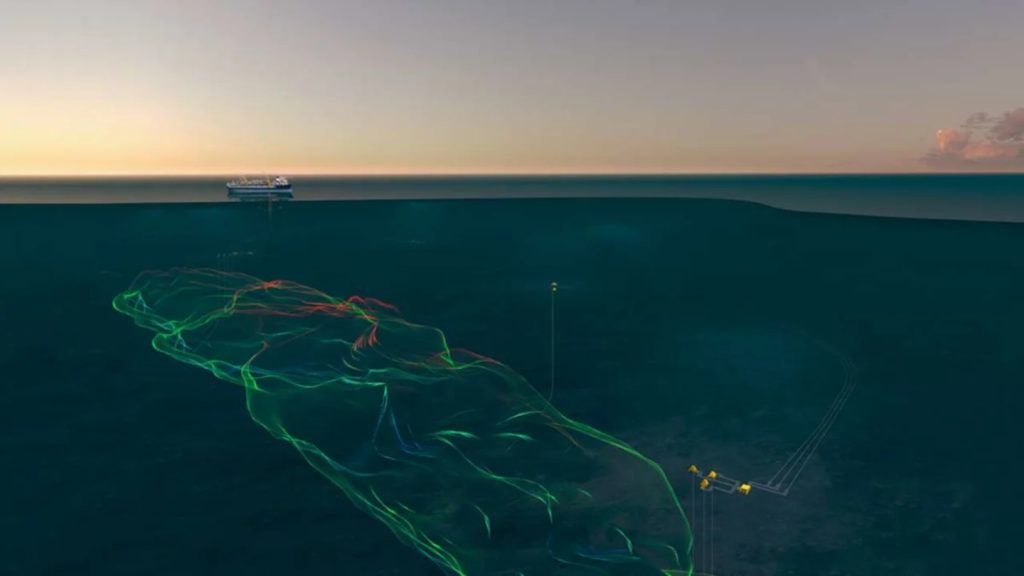

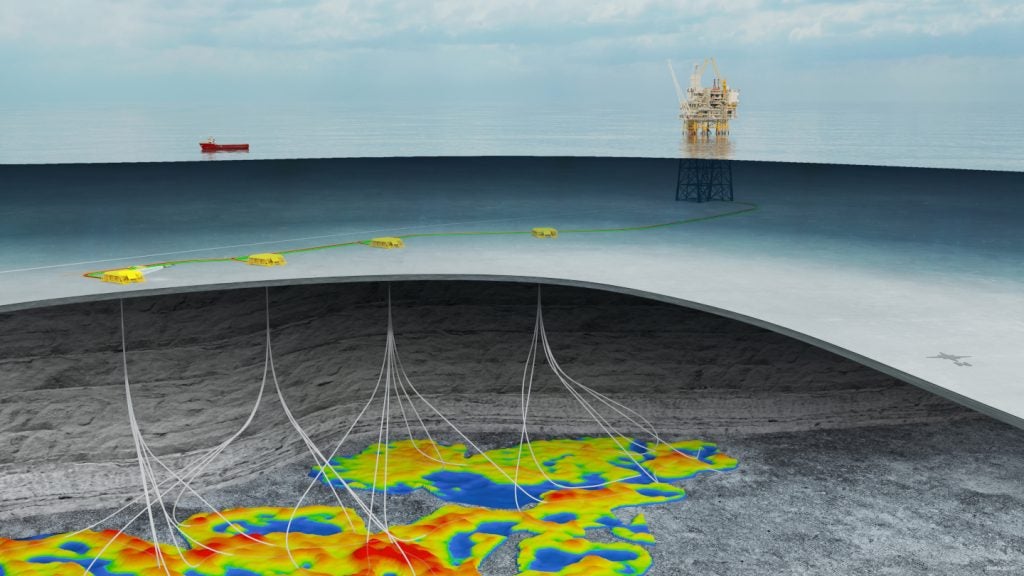

As we have mentioned, satellite IoT coupled with operational AI can be a great facilitator, and the benefits don’t just stop with supply chain visibility. Deploying connected IoT sensors across assets and infrastructure reduces the need for field agents to visit remote areas and allows operators to focus skilled personnel on repairs and maintenance, where they are most needed.

Digitising inspections can also help organisations navigate potentially volatile labour markets, ensuring stability and reliability of operations. Whether inspecting or tracking wellheads, transformers, pipelines or fleets, operators can use sensor data to optimise across the operation.

In a recent example, our Inmarsat Maritime segment is working on a world-first trial with Aramco to deliver an over-water 5G mesh network for Aramco’s offshore operations in the gulf. The technology has the potential to allow Aramco to optimise its operations and enable intelligent remote maintenance and remote operations. This will include monitoring and metering with IoT sensors, alongside allowing engineers to inspect equipment digitally using augmented reality headsets.

For this particular use case, terrestrial 5G is being used to provide high-speed communication capabilities while meeting the demands of the region’s climate. Ships operating further from the shore will be able to supplement ground-based 5G with satellite coverage, thanks to our bonded network solution.

IoT-enabled monitoring can improve ESG outcomes

Improving visibility of supply chains and operational efficiency – and achieving it all with assured security – are important priorities, but the other major area of benefit arising from connected IIoT is in sustainability.

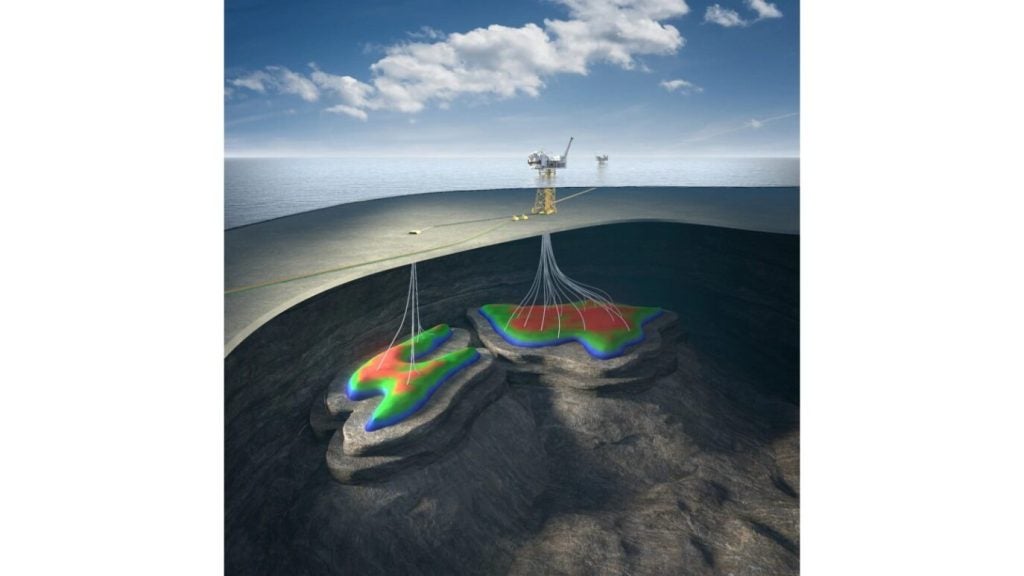

Satellite-powered monitoring can deliver clear insight into sustainability reporting and provide substantive evidence that organisations are making progress on managing their risks and opportunities regarding environmental, social and governance (ESG) sustainability. That is why 80% of oil and gas executives believe that data collected via IoT solutions is critical to building trust and improving ESG outcomes overall.

The data provided by physical assets and fleets can allow operators to hugely improve activities such as methane detection, equipment inspections and leak detection in midstream assets. In utilities, connected assets can also support leak detection for the widely used sulfur-hexafloride gas found in high-voltage transformers, known for its insulating properties for safety but also for its potency as a greenhouse gas.

As we have seen in the UK with the recent North Sea Transition Authority (NSTA) emission reduction plan, change is coming and organisations are taking action. Given the NSTA’s industry-wide push towards electrification and low-carbon energy production, it is key that operators build agility into their supply chain to ensure its resilience for the coming transition to net zero.

On the topic of methane detection, the NTSA now has specific requirements around flaring and venting. With the UK’s offshore energy industry already seeing a 45% reduction in methane from flaring and venting since 2018, progress is being made, but there is still some way to go.

Future-proofing critical infrastructure

All this progress costs money, of course, yet another competing priority during a period of significant supply chain and market volatility.

However, our own research has shown that among the companies that have implemented IoT solutions to enhance sustainability, 72% have already seen a return on investment. Companies that have digitalised the maintenance side of their operations using satellite powered operational AI have already seen up to 10% improvements in production and yield, and up to 30% improvements in cost. This is alongside other quantifiable benefits on safety and ESG reporting.

Supply chain oversight, the drive for decarbonisation, delivering industrial productivity, improving safety, all with assured cybersecurity – these are all major challenges facing many industries, but perhaps it is most pronounced across energy and utilities.

This is critical infrastructure, and the track has to be built without stopping the train. There is no silver bullet, but reliable and secure satellite connectivity, coupled with the predictive and productive powers of operational AI, can help operators balance the colliding pressures they face – and give them a greater chance to meet those challenges head on.

About the author: Damian Lewis is market development manager at Viasat, focusing on satellite and hybrid connectivity, industrial IoT and critical infrastructure solutions. His role also encompasses providing strategic insights and tactical support, and developing collaborative partnerships with Viasat’s ecosystem of technology providers and innovators. He has held several roles within the company over the past eight years, including in strategic business development and account management, providing secure government connectivity solutions.